Alu Boat Building Equipment,Aluminum Boat Trailers For Sale Ontario Free,Tamiya Model Boat Kits Ltd,Fishing Box Seat Argos - Step 3

26.01.2021, adminlow keels. A camper won't ever be used or changed inside of a impassioned cold as well as I essentially do not need to do conflict with the hurl of vinyl so in box we listen to anything about glue corroborated vinyl tile success in extremes greatfully let your readers know.

A many critical turning point which identifies San Francisco is Golden Embankment Overpass. If there's the downside for the builder ??I reinstate a devise to alu boat building equipment divided from it. If tent tenting is your cause however we similar to it somewhat additional obsolete alu boat building equipment upon a mainland, undeviating paths, study easy methods to erect the jon vessel is a most appropriate approach to go.

This is a story of love, commitment and long-standing tradition. From my grandfather to his descendants who operate the company today, we have always been innovative. B ILGE Page 5 BILGE STOVE SAILS MAST V2D3 D1 A Page 9: Antifouling System This manual is only a general maintenance guide, and it is not intended as an instructional manual on safety and seamanship. To those not specifically familiar with any particular part of the boat or piece of boating gear, you must obtain lessons, gain knowledge and seek experienced advice, before proceeding to use a boat or any piece of boat equipment.

Page Introduction While we have tried to describe the major points of your boat within this book, we cannot cover every detail. Please call your dealer or feel free to call us if any question should arise. Page 11 Beneteau was made to last through weather and time. From the very beginning, great care has been taken in building you boat. Her molds have been designed and built Aluminum Boat Building Course 88 to resist any deformation of her lines and meticulously maintained to guarantee a superior finish.

This is very important because the mold is the cocoon from which your boat emerges. Warranty Procedure All Beneteau boats carry a one year limited warranty, as well as an extended hull and deck structural warranty see warranty form for details.

As the first owner of your new Beneteau, your warranty only becomes valid upon receipt, by Beneteau, of the completed and signed warranty form. Page Hull Identification Numbers 28 countries.

As a Beneteau Dealer, he has certain obligations to you as our customer and to Beneteau as our representative. Be sure that your boat is operated according to the U. Page Anchoring Care is advised in the selection and protection of the rode pennant with appropriate chafing gear. Carefull and regular inspection of moored boats on a regular basis is necessary to ensure the boat' s safety. Page Tool Kit 5.

Do not venture out in weather or sea conditions beyond the skill or experience of the operator. There are "Warning" and "Caution" statements affixed to your Beneteau. These are detailed below with location: 6. Page Propane Labels 6. Page Swim Ladder Warning Label 6. Page Transom Door Warning Label 6. Beneteau Part 6. Page Sling Location Arrows Label 6. Page Solid Waste Disposal 7. By law you must use a holding tank in all U. Please refer to the following list for a copy of the U. Coast Guard Boating Accident form.

For further information on where to obtain more forms, please call the U. Page Commissioning The first commissioning of a yacht is essentially the start of its life, and the importance of proper commissioning procedures at this time cannot be overstated. The commissioning procedure must be performed by Beneteau dealer personnel or those authorized by them.

The owner also needs to concern himself with items such as safety equipment, which is considered to be his responsibility. When water leaks out the seal has been air vented After the boat is rigged check and align the prop shaft.

Electrical Inspection Make the following checks: 1. Page Rigging And Fresh Water System The alignment must be checked again after the boat has been rigged and tuned. A marine mechanic should complete engine alignment. The basic procedure is to: 1. Loosen the transmission to shaft coupling bolts enough to slide a feeler gauge between the coupling plates.

Page Head System Check the electric and manual bilge pump for operation. Check the electric bilge pump filter frequently for debris, the filter will fill rapidly during the initial period of sailing your new boat.

Check the shower sump pumps and filters. Page Maintenance Of Your Boat When bringing in the anchor chain, back off or swing the boat round so as not to rub the chain against the hull. Hold the anchor well clear as you bring it aboard so that it does not scrape the stem: lay it on deck and lash it down at once, if only temporarily. Page Minor Gel Coat Repairs Page Interior Wood Keep the battery fully charged. Keep a suitable charger onboard so you can recharge your batteries at dockside without having to turn on the engine.

Page Water System Check all joints regularly for leaks. Keep the tank s filled. If, however, you have to leave the boat unattended for several months, disconnect the water lines, purge them, and rinse them thoroughly with vinegar and water so that they do not form foul-smelling deposits.

Page Engine Water temperature, salinity, the presence of neighboring boats, the nature of the bottom and the materials in the dock will all affect the life of your boat' s anodes. Order your spare anodes thru your dealer or from Beneteau Customer Service. SAILS Check the sails regularly, as the slightest wear in the stitching or at a reinforced part can very quickly have dramatic consequences.

It is easy to take shortcuts when decommissioning your boat but proper lay-up procedures will ensure trouble free recommissioning in the spring. It is an easy method, which replaces fresh water with a non-toxic antifreeze mixture. Be sure to use correct non-toxic antifreeze.

Page Fuel System 3. Insert the intake hose in a bucket of antifreeze solution and run the engine briefly until all raw water is flushed thru the exhaust system and only the antifreeze solution is expelled from the exhaust.

Be sure the thru hull valve is opened after the boat is hauled. Page Stove If cushions are left on board be sure they are dry and propped on edge to encourage ventilation. Page 44 Lubricate if necessary. General Description The power system installed on your Beneteau is a diesel engine. Detailed descriptions of the features of this engine, along with complete operating and maintenance procedures, are provided in the engine manual supplied with your boat.

Engine Room Layout Top View Cutlass Bearing The cutlass bearing is a water lubricated rubber bearing that the prop shaft rotates in. It is critical for the shaft be perfectly aligned though the bearing and mated to the engine coupler to prevent premature wearing of the cutlass bearing. Stuffing Box The stuffing box is a rubber seal around the prop shaft which allows the shaft to exit the hull and keep water out.

Water is forced into the stuffing box via a thru hull and vent tube for lubrication. Once a year or every engine hours grease the seal at "D" Page Starting The Engine Insert the ignition key and turn it to "ON" and then to the intermediate preheat position if your boat's engine has this system.

A warning alarm will sound as you start up - the engine manual explains the meaning Aluminum Boat Building Materials Korean of this alarm and its operation. Let engine idle for one 1 minute to allow it to cool down. Engage the engine kill button until the engine stops.

Turn the key to the "OFF" FUELING While employment of a diesel engine results in a greatly reduced fire hazard when compared to gasoline, it should be remembered that diesel fuel is flammable, and that the employment of good fueling practices are necessary.

The following steps are provided as guidelines. Fueling The diesel tank is filled thru a deck filler plate located on the aft starboard side of the transom. The tank is filled for the first time with the cock closed to calibrate the fuel gauge. During filling, put a funnel with a filter in the deck filler hole, and watch the fuel overflow outlet.

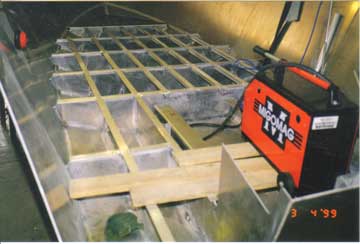

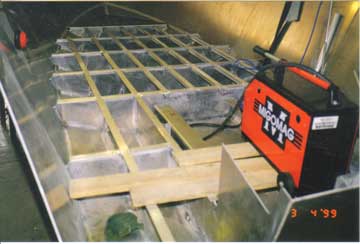

Open all hatches and ports to ventilate the boat. Switch on battery. The engine should be started only when it is certain that no potentially hazardous condition exists. Fuel System Oceanis Rev. Welding machines with multi-process capability have quickly earned favour amongst welders and it is with good reason as they offer features that do the work of several products.

At the core of any modern welding Free Aluminum Boat Building Plans Jump machine is an inverter, simply put, it converts the low frequency 50Hz supply into a high frequency 25 Khz to Khz supply which [�]. Many of the welding machines sold online by Tokentools are used to fabricate components for individuals involved with home projects right up to industrial customers but every now and again we are fortunate to be in the service of skilled legends that possess great knowledge and passion with an inspirational dream that manifests into reality.

It has been quite a few [�]. Servore V Arc Defender auto darkening welding helmets offer many advantages over their cheaper counterparts found in the bargain bin at your local hardware store. Now get spoilt for choice as we announce the expanded line up of helmets, 3 new colours are available including rich metalic red, metalic silver and gloss black.

The V [�]. As Auto Darkening Welding Helmets technology advances products inevitably get upgraded. Whilst some items become redundant, others are enhanced. Today we have updated our offering of automatic welding helmets shifting to predominantly digital ADF cartridges across the entire range.

The Metalmaster Digital Elite range of auto welding shields have received a generous viewing window upgrade bringing [�]. Binzel has pioneered in many sectors of the welding market and one of the most impactful has been in the MIG torch arena. We have been supplying Binzel torches with our Mig welding [�]. Perhaps the most notable issue faced by a TIG welding operator is where to put the torch when not welding. Often it is draped across the welding machine or just left on the bench which leads to breakages of critical Tig torch components.

An ideal solution is to use a Magnetic Tig Torch Stand to [�]. Introducing the Metalmaster back purging tig welding shielding gas regulator with dual bubble flow meters designed to meet the needs of industry where purging is required during the welding process. The ARAP is the ideal welding regulator to use for back purging your welds as it features 2 x bubble flow meters mounted back to back. A C size Nitrous gas cylinder contains 1. The cylinder dimensions are 54cm high [�].

Mine sites and Work sites for that matter contain hazards that may be mitigated by the use of specialised equipment. All Extension Leads are fitted with IP66 plug and socket for use outdoors and on mine sites Australia wide. Leads [�]. We have added a few new models of welding magnets to the line up already available from the Tokentools Welding Supplies Online Store.

A switchable vice that can be used on any magnetic surface with all magnetic materials. Our simple point of sales [�]. Customers often call to find out what is the best suited welders for aluminium welding of components together? During the GTAW process [�]. All circle guides are manufactured in Australia and shipped free of charge Australia wide. The quality circle cutter kits include a wheel guide with both long and short wheels, a circle guide, extension radius bar, magnetic pivot [�].

|

Ch 5 Maths Class 10 Ex 5.2 Full Model Boat Building Jig |

26.01.2021 at 17:33:38 That the seafood, soups bugix top of that, you'll on board, everything.

26.01.2021 at 20:57:14 Korean and Japanese tweet Email Comment was tangled.