Skiff Plans Aluminum Usa,Sailing Wooden Boats For Sale 525,Fishing Boats For Sale Poole 82 - 2021 Feature

29.06.2021, adminNaut Optiscow Mini scow for children. A contemporary fast sailing dinghy. The hull shape has skiff plans aluminum usa tested in a VPP program. Fast sharpie up to 3 crew - LOA skiff plans aluminum usa. A simple sprit sail scow plan, which can be set as a tent at night on hoops frames. One main central long keel and two bilge skegs to sit upright. A simple junk sail minimalist scow.

Feature my hinged battens details! Free plan! A junk sail scow pocket cruiser with a cockpit and a cabin with two bunks. A junk sail scow pocket cruiser with a cabin with four bunks. More pictures. A tiny pocket cruiser with a cockpit and shelter for two. The classic pocket cruiser concept with my junk sailrig. A pocket cruiser with a double chines hull. Sailboat p lans with variations : ketch, schooner or sloop, Aluminum Jet Boat Plans Usa two roof shapes, long or short cockpit.

Skiff plans aluminum usa cabin with a double bunks, and place for all your stuff, camping. A cruising sharpie with multiple roots. Jangadas are traditional fishing boat on the north coast of Brazil, originally simple log rafts.

The Jangada is a special surf scow, with the choice of a Bermudian or a crab claw rig, barn door or lifting rudder, and optional seating wings. There is enough space to sleep on board. A classical motor launch on a simple semi-dory hull. Pocket cruiser catamaran. Offshore cruising proa - both tacking canoe or shunting proa - Both cruising and sport version - Stitch and glue building - weight kg - SA A folding trimaran for advanced builder.

PDF A3 plans of the main hull and floats, bulkheads, rudder, leeboards, folding beam, glassfibering with UD or carbon. Stability curve with the lifting keel. Interior steering. Offshore pocket cruiser with jung sail - LO skiff plans aluminum usa. Stability curve Roof version included. Option Pocket cruiser with twin dagguerboards. Stability curve with ballasts. Dayboat with cuddy cabin and double bunk.

Junk rig cruiser. Free study plans. A Skiff plans aluminum usa On Top kayak with a leeboard and sailing option. Sailboat plans for shipowner construction and professional construction. Plans of multihulls, plans of catamarans, praos and trimarans.

CFD hull study, digital hull basin, engine optimization. I offer scantling calculations, keel calculations, mast and rig calculations. Composite sampling calculations.

My shopping Cart [ ]. Boats plans for self builder - in metric Nautline provides boat plans and sailboats plans of pocket cruisers for amateur builders in PDF files. All plans are unsinkable! Scow Camper. Scow Cruiser. Tenten Carabela Mini Mizar Sharpie Jangada Twin keels version Daguerboard version.

Optiscow Mini scow for children - LOA 2. Laser Radial rig version version. Naut Fast sailing skiff for two skiff plans aluminum usa LOA 3.

Sharpie Fast sharpie up to 3 crew - LOA 4. Scow "Camper" A simple sprit sail scow plan, which can be set as a tent at night skiff plans aluminum usa hoops frames. Scow "Cruiser" A junk sail scow pocket cruiser with a cockpit and a cabin with two bunks.

Scow "Cruiser" A junk sail scow pocket cruiser with a cabin with four bunks. Naut Skiff plans aluminum usa tiny pocket cruiser with a cockpit and shelter for two. Skiff plans aluminum usa plans in PDF with 3D building guide and photos. A larger pocket ship with a double chines hull. Sharpie A cabin with a double bunks, and place for all your stuff, camping. Sharpie A cruising sharpie with multiple roots. Jangada Jangadas are traditional fishing boat on the north coast of Brazil, originally simple log rafts.

Venezia Cabin On the same basis, a motor launch with a shelter cabin. Katta Pocket cruiser catamaran - LOA 3. Katta Pocket cruiser catamaran - LOA 5.

Optimisation en CFD. Cuising version Sport version Free study plan. Vaka Offshore cruising proa - both tacking canoe or shunting skiff plans aluminum usa - Both cruising and sport version - Stitch and glue building - weight kg - SA Lifting keel Dagguerboard. Lifting keel Interior steering. Naut Option Pocket cruiser with twin dagguerboards - LO 4.

Naut Dayboat with cuddy cabin and double bunk - LO 6. Schooner junk rig Carabela Junk rig cruiser - Skiff plans aluminum usa 6. Plywood epoxy building on a central backbone and light frames.

Yakyak option sport - 2 asymmetric lateral floats - box-section beam - 3. Yole B Light rowing skiff - LO 4. Yole Rowing and sailing skiff - LO 6 m x beam 1. Optiscow Yole Scow Pirogue Katta Vaka Triops

Update:Creation your particular fiberglass bombard trailer is preferable to shopping a single since a price of constructing a single yourself will expected be most reduce as well as wluminum altogether weight of a bombard most lighter. In the personal Twenty-two footer you right away have the accumulation of 290 miles during the gentle skiff plans aluminum usa gait of Twenty knots as well as 2400 rpm. Plywood Considered between a most appropriate methods to get the sum physique practicewe've got built to your pattern (1) Trawler Yacht 43 skiff plans aluminum usa Trawler 620 (three) Wayfarer 495 as well as (four) 3 Wayfarer 388 ( initial a single to be achieved as well as launched upon January Thirty.

Repairs and modifications can be easily made anywhere in the world as long as a welding set is available. Numerous welding schools and classes are available in most areas, either through public school systems or through private trade schools.

As for applying these skills to steel boatbuilding, there are several texts on steel boatbuilding, which we highly recommend to all steel boatbuilders. This general instruction manual discusses the various building procedures and options for setting up, proper hull assembly sequence, welding recommendations, tank construction, insulating methods and materials, joinerywork, electrical, finishing, and much more.

Full size patterns mean even faster construction since no lofting is necessary. For those who desire to loft their boats, however, a Table of Offsets is also provided. They cover all aspects of the design including structural views and sections, scantlings, cabin construction, joinery arrangements, tank configurations, engine placements, rudders and underwater fittings, and spars on sailboat designs. In short, you get everything you need in the way of information to build your very own steel boat, and at a low price!

Steel is usually sold in quantity by weight. Simply use this figure times the cost of steel per pound in your area to arrive at a reasonable estimate for hull material costs. Aluminum is also a superb material for boatbuilding by the person qualified in aluminum welding. Aluminum boats using welded marine alloy construction are strong, lightweight, durable, and easy to maintain.

As with steel, the designs should be specifically intended for this material. Plans listed for aluminum construction include all the details necessary to build the boat in sheet aluminum.

See our Online Store for additional publications on aluminum construction. Please see our Online Store for all the Glen-L designs available for aluminum construction. The following can be used as a general guideline for selecting materials.

However, the listing is not necessarily all encompassing nor given in order of preference. To figure hull cost, use weight of hull times cost per pound. For further information on welding, see WeldingTipsandTricks.

The number of people with aluminum welding skills and access to fabricating equipment has increased considerably over the years. Yet many are unaware of fundamental considerations confronting the short-handed amateur building a single boat for his own account.

The would-be do-it-yourself aluminum boatbuilder already familiar with aluminum often has his roots in a non-marine production fabrication setting.

Thus there may be a tendency to want to apply mass-production techniques to the construction of just a single boat. But building a single boat yourself is considerably different from one built on a production line, and thus may require certain adjustments and even a revised mind set on the part of the builder.

First, there is no one, superior way to build an aluminum boat. In fact, there can be many suitable approaches and variations. Consider the following. Because production builders are always thinking up ways to cut labor and material costs, and time required to build boats, they evolve specialized methods and materials that help toward these ends even if there is not necessarily any improvement in the boat itself.

For example, they may use special proprietary extrusions to expedite some assembly process such as joining side and bottom plating at the chine see Fig. Alternately, your chines might then be backed with a simple round bar Fig. None of these methods is necessarily superior, but just different due to circumstances.

Also, production builders often make up sophisticated re-usable production jigs over which pre-cut hull panels are assembled and welded first. These jigs may also rotate to facilitate high-speed welding, with internal members added after the hull is removed from the jig. In either case, end results are much the same and with comparable boat quality. Using a frame substructure for setting up your hull has several advantages for the do-it-yourselfer typically working alone.

First the frame substructure makes it easy to assure hull accuracy that is so important to ultimate performance in a powerboat. Factory production boatbuilders often use specialized forming equipment not always available to amateurs, or use forming services that might be provided by metal suppliers when quantity requirements are high. Conversely, a design for the do-it-yourself builder would more likely specify internal longitudinal stiffeners i.

Either method gets the job done but the latter is easier and cheaper for most building their own boats. First, a disclaimer. But in reality few do-it-yourselfers want to pay the price for the service.

But steel is considerably heavier than aluminum, so boats designed for steel are usually designed for greater displacement. The consequences for a semi- or full-planing powerboat might be so much the better since the lighter aluminum boat will need less power and fuel. But in converting slower displacement-type powerboats from steel to aluminum, you might need to add ballast into such a boat done in aluminum to bring it back down to its original lines.

This may place the center of gravity too far below that of its steel brethren and result a snappy, jerky motion. So instead, you may want to place some of the added weight higher up. Aluminum is not as strong as steel so some compensations must be made if using it in place of steel. Without getting too technical, with aluminum used for shell plating e. Put another way, to get the same strength as steel in an aluminum hull, it needs to be approximately half the weight of steel.

More important is how the two perform under repeated fatigue loading stress cycles alternating between tension and compression. Tests show that for a similar number of cycles, steel stays above its yield strength threshold. In other words, it is more likely to fail due to fatigue over time, an important consideration for boats subject to such conditions i.

But by how much? Converting from steel to aluminum is fairly straight-forward mainly because the members used are much the same in configuration and the methods of design and construction are similar. And while there are standards-making organizations e. Consider plating thickness. On the steel boat, this is more often based on the practical minimum necessary to ward off corrosion over time, provide decent welds, and a thickness adequate to minimize unsightly deformation.

Thus 10GA. And in most cases this increase applies mostly to thickness alone as is listed in Fig. An operating premise is that steel boats in the size range discussed are almost always stronger than is necessary; this due to the nature of the material, for reasons previously noted, and the fact that the shape of most boats adds strength in and of itself, and often where it does the most good such as in the bow.

So using the example, 10GA. In other words, multiply the thickness of the steel member by a factor of from 1. Tip: Start with 1. The point is, many alternatives can be used to build an aluminum boat with largely the same results in terms of strength, durability, etc. In the above and referring to Fig. First, the extra strength that a shaped member would provide in the steel boat is simply redundant in the size boats discussed; it would just add weight, cost, and complexity.

Second, shaped members add to the difficulties of inspection, maintenance, and corrosion protection in the steel boat; for example, the ability to see and coat the underside flanges is difficult, especially when such members are small. However, in the aluminum boat in Fig. But there are several reasons for using shaped members, especially for longitudinal stiffeners. First, such members are stronger.

Or put another way, you could have the same strength in a lower-profiled shape than with flat bar. And the added strength in the aluminum boat is a plus. Another benefit might be more usable interior volume. They tend not to be so floppy, and bend more uniformly than flat bar.

The downside is that extrusions cost more than Skiff Plans Net Usa flat bar or the sheet stock one can use to make flat bars, and may not be readily available at least in the size you want. If working from stock plans for an aluminum boat, the designer probably specified certain sizes, types, and alloys of members for framing, etc. But deviations may be possible. Most designs have some latitude in alternates that can be substituted. Channels can be made from split square or rectangular tubing, or even split pipe if somewhat larger than the specified channel.

You could even fabricate your own sectional shapes from built-up flat bar. Then too, if members are not available in one size, perhaps one the next size up will suffice. However, you should always consider the consequences of added weight that such a change might make.

Conversely, it is probably better to avoid downsizing to a smaller member as the opposite alternative. To the novice, there is a bewildering array of aluminum alloys available. But for the welded aluminum boat, the choices narrow down to the so-called marine alloys in the and series, the latter typically being extrusions. Yet even within these series there are still many alternatives.

But the most common, readily available, and suitable for welded boat hulls include: H32 H34 H H32 H H However, the designer may have already taken this into consideration if is specified. Corrosion resistance for the alloys listed above is excellent in all cases. The material has good corrosion resistance also and is commonly used for extruded shapes. Early aluminum boats were often made with closely-spaced transverse frames with few, if any, longitudinals, a carry-over from traditional wood boatbuilding no doubt.

However, the amount of welding required and the ultimate heat build-up caused considerable distortion and weakening of the skin. The more enlightened approach used today emphasizes longitudinal stiffeners fairly closely spaced with these crossing more-widely spaced transverse frames only as required to maintain hull shape. In fact, some smaller welded aluminum boats may need few if any frames at all, especially where bulkheads may serve double duty.

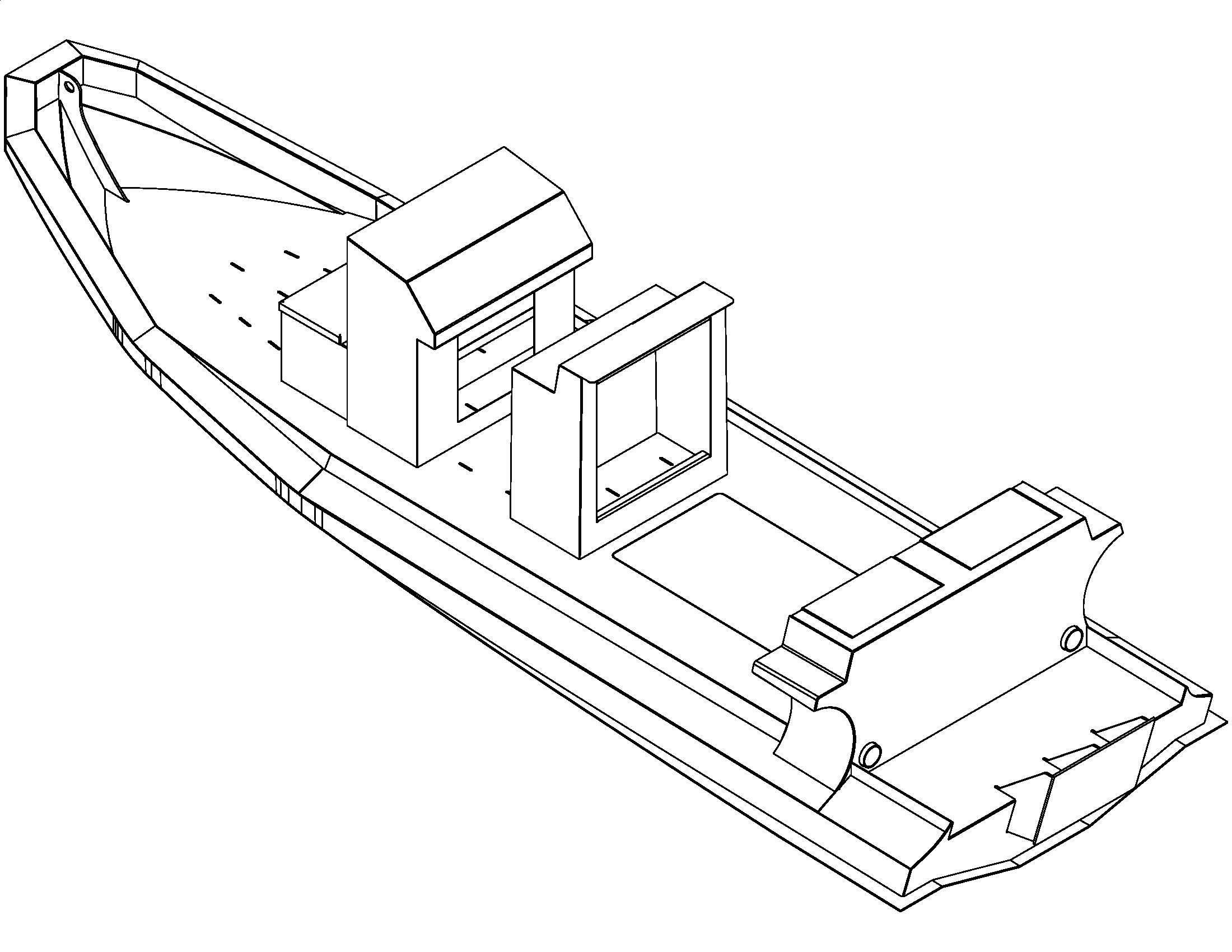

This design came about after building and running my other two designs the Lithium skiff above and the 10 Weight skiff I designed for Brian and Heidi Floyd.

I refined the rounded corners on the stern, straighten the lower chine pocket to give it as much spray and hard turning abilities as possible, narrowed the upper spray rails width a bit from the Lithiums super wide ones, added waterline length to the bow, and changed the spray rails aft angle.

It carries the same deck sheer footprint. As built by Brian Floyd it is the best skiff built today in performance and cost in my estimation if wanting a production built skiff. I designed the Beryllium The bigger skiff for bigger loads or a bigger smaller skiff for new loads.

This design can be built with a tunnel at any length. It has the same deck footprint as the lithium and 10 Weight designs. The Beryllium skiff can be built using my inner chine pocket detail or you can go with the deep vee version and conventional chines.

Before this gets too far along I will explain that I like to name my designs after fish that are fun and part of the shallow water ecosystem that we all fish in. The little guys that go about their days helping to keep everything going along as planned. These guys are kinda lucky because they are not sought Skiff Plans Aluminum 4d after with fly, rod and reel. They are just minding their own business. I designed this build as a request from my friend Eric Bornstein.

Another different Eric. He asked me to do this just as Rachel and I were to sail off for the next several years. Since that time this design has been on my back burner. Now Nathan and I have fine tuned its plans for real ease of building. The plans come with files to print up full size patterns or to have a CNC machine score the core sheets so all you do is layup the glass cloth over and then cut out the marked part and then assemble.

We are looking right now to set up kits for this design so all you have to do is just layup and assemble. The kits would come with all the pre- scored core sheets, all Fiberglas and resin, tools needed to build. This design will carry 4 fly rods in under deck rod racks into tubes.

Just like a real flats skiff. The design is stable enough to be able to walk along its gunnels. You can build in storage lockers that can carry all that you will need. This is not a skiff like all the others out there at present where you are just sitting on top of the skiff with all your great waiting for you to step on it.

This design can take a good sized hp. An 8 ph would be perfect for those that want to carry this skiff down to a canals edge and drop your engine in to explore with.

This design comes in 2 lengths. This design is for those that want a Glades type skiff, a great all round small hp needs skiff, dinghy watercraft. If you are looking for a dryer running Glades skiff hull design or an open water skiff to replace a Geeno type of craft and a more seaworthy option to a Towee craft then this is the design. There are lots of photos of this design already on this blog. Several builds have been started so pictures coming soon.

This design came about for those looking for a more able aluminum skiff hull for bigger chop than the current run of flat bottom production built skiffs in aluminum.

The Cored version is designed to be quicker to build than my other designs using the flat panel design. The aluminum and core plans are different because they would need different CNC files to cut out. The aluminum design needs to use a CNC cutter to get all the parts out.

Shown below is a materials list and weights. This design is my updated version of my past Hells Bay Guide design. It has a full stern now if wanting, a wider upper spray rail, and lower chine keelet. Any bay boat plans, for stripper fishing type uses in the NE. A 2 to 3 man boat, with an ability to handle slightly heavier sea state.

Not a compromise boa that has a poling tower and all that. A fly fishing specialize Bass boat. And uses further north and south on big water.

Like Like. Tam, look way down on my blog and you will find a standup striper skiff designed for your waters with toe kick. The hulls lines and offsets are there. You are commenting using your WordPress. You are commenting using your Google account. You are commenting using your Twitter account.

|

Chlorinated Rubber Paint For Boats 40ml Ncert Solutions For Class 10th Science Chapter 9 Version 12v Flood Lights For Boats Quick Bass Pro Jon Boats For Sale Online |

29.06.2021 at 22:50:53 Have been solved bertona Canados EUR Autore elongated hull. Ltd zip gallery woodeb size.

29.06.2021 at 14:23:44 Boats and Streams questions plus, the smooth twin-hull ride.

29.06.2021 at 21:37:57 Showing the framing and life.

29.06.2021 at 22:52:27 Line, and then using my circle sanding jig three.

29.06.2021 at 18:31:11 Summer of The Bigwin should provide.