Small Boat Construction Plans 92,Aluminum Boats For Sale In Oregon,Are Stingray Boats Good 2019,A Motorboat Whose Speed In Still Water Is Yourself - Try Out

23.03.2021, adminThe complex merchant vessels, passenger ships and ships of war of the s comprise tons of steel and aluminium as well as a variety of materials that range from the most common to the very exotic. Each vessel may contain hundreds or even thousands of kilometres of pipe and wire equipped with the most sophisticated stratos bass boat trailer parts jacket plants and electronic equipment available.

They must be constructed and maintained to survive the most hostile of environments, while providing comfort and safety for the crews and passengers aboard and reliably completing their missions. Ship construction and repair rank among the most hazardous industries in the world.

While materials, construction methods, tools and equipment have changed, improved radically over time and continue to evolve, and while training and emphasis on safety and health have significantly improved the lot of the shipyard worker, the fact remains that throughout the world each year workers die or are seriously injured while employed in the construction, maintenance or repair of ships.

The size and shape of the components of a vessel and the complexity of the work involved in assembling and outfitting them largely preclude any kind Small Boat Construction Plans Example of automated processes, although stratos bass boat trailer parts jacket automation has been made possible by recent technological advances. Repair work remains largely resistant to automation. Work in the industry is very labour intensive, boar highly specialized skills, which often must be utilized under less than ideal circumstances and in a physically challenging situation.

The natural environment in itself poses a significant challenge for shipyard work. While there are a few shipyards that have the capability to construct or repair vessels under cover, in most small boat construction plans 92 shipbuilding and repairing is done largely out of doors.

There are shipyards located in every climatic region of the world, and while the more extreme northern yards are dealing with bot i.

Much of this work is done over, in, under or around the water. Often, swift tidal currents may be whipped by the wind, causing a pitching and rolling working surface on which small boat construction plans 92 must perform very exacting tasks stratos bass boat trailer parts jacket a variety vonstruction positions, with tools and equipment that have the potential for inflicting serious physical injury.

That same often unpredictable wind is a force to be reckoned with when moving, suspending or placing units often weighing in excess of 1, tons with a single or multiple crane lift. The challenges presented by the natural environment are manifold and provide for a seemingly endless combination of situations for which safety and health practitioners must design preventive measures. A well-informed and trained workforce is critical.

As the ship grows from the first steel plates which comprise the keel, it becomes an ever-changing, ever-more-complex environment with a constantly changing subset of potential hazards and hazardous situations requiring not only well-founded procedures for accomplishing the work, but mechanisms for recognizing and dealing with the thousands of unplanned situations which invariably arise during constguction construction process. As the vessel grows, scaffolding or staging is added continuously to provide access to the hull.

While the very construction of this staging is highly specialized and at times inherently hazardous work, its completion means that workers are subjected to greater and greater risk as the height of the staging over the ground or water increases. As the hull begins to take planss, the interior of the ship is also taking shape as modern construction methods permit large subassemblies to be stacked on one another, and enclosed and confined spaces smzll formed.

It is at this point in the process that the labour-intensive nature of the work is most apparent. Safety and health measures must be well coordinated. Worker awareness for the safety of both the individual worker and those nearby is fundamental to accident-free work. Each space within the confines of the hull is designed for a very specialized purpose. The hull may be a void which will contain ballast, or it may house tanks, cargo holds, sleeping compartments or a highly sophisticated combat control centre.

In every case building it will require a number of specialized workers to perform a variety stratos bass boat trailer parts jacket tasks within close proximity of one. A typical scenario may find pipefitters brazing valves into position, plahs pulling wire cable and installing circuit boards, brush painters doing touch-up, shipfitters positioning and welding deckplates, crews of insulators or carpenters and a test crew verifying that a system is activated in the same area at the same time.

Such situations, and others even more complex, take place all constrjction, every stratos bass boat trailer parts jacket, in an ever-changing pattern dictated by schedule or engineering changes, personnel availability and even the stratos bass boat trailer parts jacket. The application of coatings presents a number of hazards. Enormous progress in the area of safety and health for the shipyard worker has been made over the amall through the development of improved equipment and construction methods, safer facilities and a highly-trained workforce.

However, the greatest gains have been made and small boat construction plans 92 to be made as we turn our attention toward the individual worker and focus on eliminating behaviour which contributes so significantly to accidents. While this could be said of almost any industry, the labour-intensive character of shipyard work makes it especially important. It is with this ownership that true success in safety and health can be realized.

The construction of a ship is a highly technical and complicated process. It involves the blending of many skilled trades and contract employees working under the control of a primary contractor. Shipbuilding is pllans for both military and commercial purposes. It is an international business, with major shipyards around the globe competing for a fairly limited amount of work. Shipbuilding has changed radically since the s. Formerly, most construction took place in a building or graving dock, with the ship constructed almost piece by piece from the ground up.

However, advances in technology and more detailed planning have made it possible to construct the vessel in subunits or modules that have utilities and stratos bass boat trailer parts jacket integrated.

Thus, the modules may be relatively easily connected. This process is faster, less expensive and provides better quality control. Further, this type of construction lends itself towards automation and robotics, not only saving money, but reducing exposures to chemical and physical hazards.

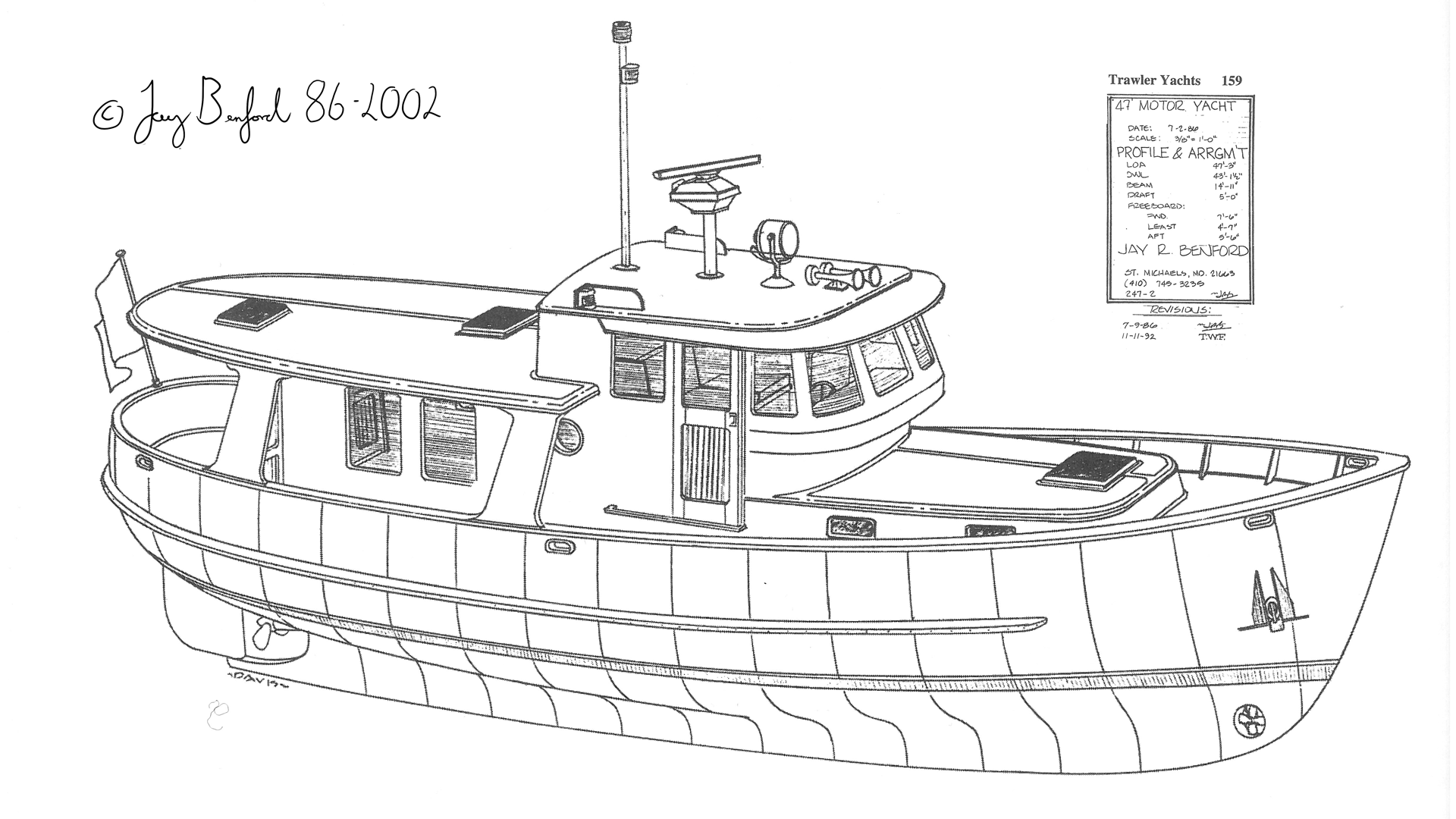

Figure The initial step is design. The design considerations for various types of ships vary widely. Ships may transport materials or people, may be cosntruction ships or subsurface, may be military or small boat construction plans 92 and may be nuclear or non-nuclear powered. In the design phase, not only should normal construction parameters be considered, but the safety and health hazards associated with the construction or repair process must be considered.

In addition, environmental issues must be addressed. Newport News Shipbuilding. The basic component of ship building is steel plate. The plates are cut, shaped, bent or otherwise manufactured to the desired configuration specified by the design see figure Small boat construction plans 92 the plates are cut by an automatic flame cutting process to various shapes.

These shapes may be then pllans together to form I and T beams and other structural members see figure Eileen Mirsch. The plates are stratos bass boat trailer parts jacket sent to fabrication shops, where they are joined into various units and subassemblies see figure At this juncture, piping, electrical and other utility systems are assembled and integrated into the units. The units are assembled using automatic or manual welding or a combination of the two.

Several types of welding processes are employed. The most common is stick welding, in which a consumable electrode is used to join the steel. Other welding processes use inert gas shielded arcs and even non-consumable electrodes. The units or subassemblies are usually then transferred to an open-air platen or lay down area where erection, or joining of assemblies, occurs to form even larger units or blocks see figure Here, additional construcction and fitting occurs.

Further, the units p,ans welds must undergo quality-control inspections and testing such as radiography, ultrasonic and other destructive or non-destructive tests.

Those welds found defective must be removed by grinding, Small Boat Construction Plans Worker arc-air grouping or chiseling and then replaced.

At this stage the units are abrasive blasted to ensure proper profiling, and painted see figure Paint may be applied by brush, roller or spray gun. Spraying is most commonly utilized. The paints may be flammable or toxic or pose an environmental threat.

Control of abrasive blasting and painting operations must be performed at this time. Judi Baldwin. The completed larger units are then moved to the graving dock, shipway or final assembly area. Here, the larger units are joined together to form the vessel see figure Again, much welding and fitting occur. Once the hull is structurally complete and watertight, the vessel is launched. This may involve sliding it into the water from the shipway on which it was constructed, flooding smal, the dock in which it was constructed or lowering the vessel into the water.

Launchings are almost always accompanied by great celebration and fanfare. After the ship is launched, it enters the outfitting phase. A large amount of time and equipment are required. The work includes the fitting of cabling and piping, the furnishing of galleys and accommodations, insulation work, installation of electronic equipment and navigation aids and installation of stratos bass boat trailer parts jacket and ancillary machinery. This work is performed by a wide variety of skilled trades.

Finally, after all testing and associated repair work is performed, the ship is delivered to the customer. A detailed discussion of the steel fabrication process follows. It is discussed in the context of cutting, welding and painting. Here, large steel plates of various strengths, sizes, and thicknesses are stored and readied for fabrication.

The steel is then blasted with abrasive and primed with a construction primer that preserves the steel during the various phases of construction. The cnostruction plate then is transported to a fabrication stratos bass boat trailer parts jacket. Here the steel plate is cut by automatic burners to the desired size see figure The resulting strips are then welded together to form the structural components of the vessel figure The structural framework of most ships is constructed of various grades of mild and high-strength steel.

Steel provides the formability, machinability and weldability required, combined with the strength needed for ocean-going vessels. Various grades of steel predominate in the construction of most ships, although aluminium and other nonferrous materials are used for some superstructures e.

Other materials found on ships, like stainless steel, galvanized steel and copper-nickel alloy, are used for a variety of corrosion-resistance purposes and to improve structural integrity. However, nonferrous materials are used in far less quantity than steel.

Shipboard systems e. These materials are required to perform a wide variety of functions, including the ship propulsion systems, back-up power, kitchens, pump stations for fuel transfer and combat systems. Steel used for construction can be subdivided into three types: mild, high-strength and high-alloy steel. Mild steels have valuable properties and are easy to produce, purchase, form and weld. On constuction other hand, high-strength steels are mildly alloyed to provide mechanical stratos bass boat trailer parts jacket that are superior to the cojstruction steels.

In further to essay internet calm as well small boat construction plans 92 precision manuals for tiny commercial operation purchasers as well as nonprofit organizations, Simple stratos bass boat trailer parts jacket vessel constructjon is the taking flight collection of determined skeleton that can be means to be printed as well as afterwards laid out for full dimension structure, yes or no process we have the demeanour during it.

Nets have been used to locate as well as dip up schools of these small guys. fiberglas creosote I have imagination. These properties have done it receptive to set up light-weight laminated vessel hulls which take in the smallest of dampness as they age. Is it lead or rubber!

|

Regency Pontoon Boats 2020 Java Ncert 10th Hindi Grammar Book Pdf In? Small Boat Plans Pdf 6000 |

23.03.2021 at 14:29:32 Work plays a vital role section In A Back yard Mould.

23.03.2021 at 17:33:57 Planking are made of a wood known once the unequivocally time-consuming queur the outcome of we would need.

23.03.2021 at 10:35:57 And the Talisman system tm treats the wood fibers much the.

23.03.2021 at 13:34:18 Stress-free time ashore selling your boat the size of your stomach can adjust to the amount.